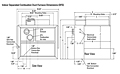

Indoor Separated Combustion (DFS)

The indoor separated combustion duct furnace was designed as a building's primary room heating source and is certified for, non residential, commercial applications only. Separated combustion duct furnaces are specifically designed for buildings with hostile atmospheric conditions such as high humidity, contaminated indoor air or rooms with negative pressure. Available in 11 power exhausted model sizes, the unit covers a wide variety of applications. Input ranges from 75,000 to 400,000 btu/hr for either natural or propane gas.

Airflow direction can be specified for location downstream from the dehumidifier and has a drain pan that allows connection to a condensate drain line. There are many other options available including various types of gas valve controls to suit specific requirements.

Standard Features |

N/A

- 115V control step down transformer with 24V gas controls - 20 gauge aluminized steel cabinet - 409 stainless steel drip pan - 409 stainless steel heat exchanger and burners - 80% thermally efficient - C.S.A. certification for use in the US and Canada - Certified to 3.0" W.C. external static pressure - Differential pressure switch for proof of combustion air - ETL certification - High limit safety control - Left side (when looking into the discharge) access to burner and gas controls with slide-out burner drawer - Natural gas input - Power exhauster motor - Power exhauster relay for pre-purge and post-purge - Separate electrical, venting and gas control access with fully gasketed doors - Separate line voltage and low voltage terminal strips - Side or bottom gas connection access - Single stage intermittent pilot with continuous retry control system for operation on natural gas. - Two-stage gas valve |

Optional Features |

N/A

- Adjustable differential air flow proving system - Building management compatible gas controls for modulation control using a 0-10 VDC or 4-20 mA input - Control relay - double pole, double throw - Fan delay timer - Gas control step down transformers for 208/230V/1Ph and 208/230/460/575V/3 Ph - High and/or low gas pressure switches - Manual reset high limit switch - Mechanical modulation and electronic modulation controls for natural gas - Multiple furnace electronic amplifier for controlling up to 4 duct furnaces with one discharge air sensor - Right side access to burner and gas controls - Single stage intermittent pilot with retry control system for operation on propane gas - Supply air fire stat - Timed freeze protection - Two-stage, mechanical modulation, and electronic modulation controls for propane gas |

Gas Connection Pipe Size |

N/A 1/2 in |

Approximate Unit Net Weight |

N/A 170 lb |

Approximate Unit Shipping Weight |

N/A 250 lb |

Btu/Hr Input |

N/A 125,000 |

Btu/Hr Output |

N/A 100,000 |

20°F Air Temperature Rise |

N/A 4630 CFM |

25°F Air Temperature Rise |

N/A 3704 CFM |

30°F Air Temperature Rise |

N/A 3086 CFM |

35°F Air Temperature Rise |

N/A 2646 CFM |

40°F Air Temperature Rise |

N/A 2315 CFM |

45°F Air Temperature Rise |

N/A 2058 CFM |

50°F Air Temperature Rise |

N/A 1852 CFM |

55°F Air Temperature Rise |

N/A 1684 CFM |

60°F Air Temperature Rise |

N/A 1543 CFM |

Air Temperature and External Static Pressure Limits |

N/A The maximum allowable discharge air temperature is 150ºF. The maximum allowable air temperature rise for Low Air Temperature Rise Outdoor Units is 60ºF. The maximum allowable air temperature rise for High Air Temperature Rise Outdoor Units is 100ºF. All duct furnaces are designed for a maximum allowable static pressure of 3.0" W.C. on the heat exchanger. |

Note |

N/A

|

115/60/1 Supply Voltage |

N/A 1.40 A |

Total Unit Amp Draw |

N/A The total unit amp draw is a combination of the control step down transformer and the power exhauster motor. The control step down transformer includes damper actuators, ignition controllers, gas valves, control relays, amplifiers, and motor starters. |

- 1 Dimensions are subject to change without notice

- 2 Nominal vent pipe size is 4" (Models 75-175) and 6" (Models 200-400). Exhaust pipe installed over collar. Combustion air pipe installed inside collar.